- #Fastcam outline how to#

- #Fastcam outline install#

- #Fastcam outline upgrade#

- #Fastcam outline software#

- #Fastcam outline Pc#

We may collect non-personal identification information about Users whenever they interact with our Site.

We will collect personal identification information from Users only if they voluntarily submit such information to us. Users may, however, visit our Site anonymously. Users may be asked for, as appropriate, name, email address, mailing address, phone number, credit card information and verification. We may collect personal identification information from Users in a variety of ways, including, but not limited to, when Users visit our site, register on the site, place an order, fill out a form, and in connection with other activities, services, features or resources we make available on our Site. This privacy policy applies to the Site and all products and services offered by Rocky Mountain High Speed, LLC. As duty cycle, I must say that 10 min waiting is enough to cool down the tip to avoid this problem.This Privacy Policy governs the manner in which Rocky Mountain High Speed, LLC collects, uses, maintains and discloses information collected from users (each, a “User”) of (“Site”). But I must say that two hours of cutting operation is really long. To cool down the nozzle, I will not recommend to dip it in water….thermal shock. (since mid 2007 all CNC cutting machines have the memory upgraded) 09 After a long time cutting, the tip become very hot, what should I do to cool down it? #Ĭoncerning the hot tip problem, the problem leading to self-extinguish the flame, can be observed, after two hours, the flame is becoming unstable and need adjustment of the flow of the cutting oxygen. Please note, that the loading time will be 20 seconds and when cutting if you want to visualize the cutting shape, it will take 20 seconds as well It increase the memory size from 8Kb to 26 Kb, allowing you 1024 lines program instead of 540 before. This upgrade, will allow you to work big art work or nesting files.

#Fastcam outline upgrade#

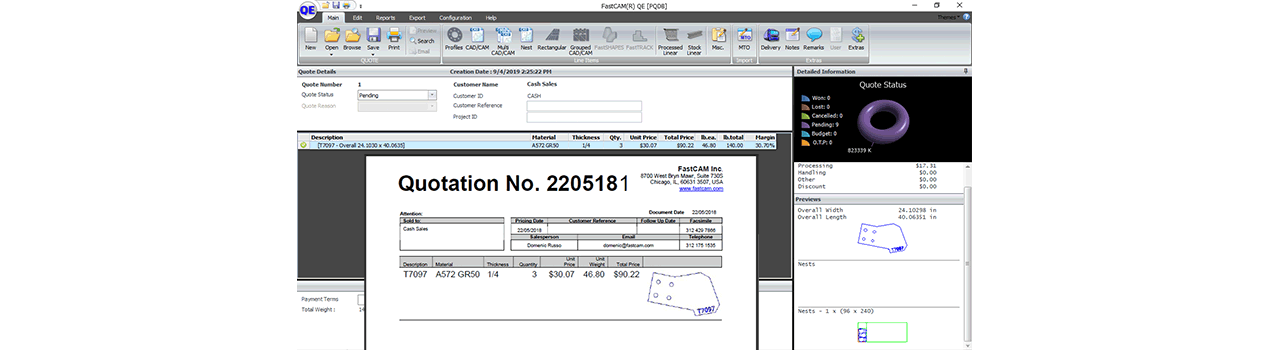

08 What’s The benefit of upgrade the software? # dxf extension FastCAM may translate your drawings into CNC cutting programs.

#Fastcam outline software#

If your solid works CAD software may save the file in. 07 I currently use solid works (sheet metal), Can FastCAM translate into CNC cutting program? # With the optional FastCAM Outline Software you may translate a picture file (.jpg. Change to another computer and have a try.Ġ6 Will software import and convert scanned images? #.Reinstall window7 system ,install MTC program firstly.The causation: When Uninstalling software, it is failed to delete all relative files.

#Fastcam outline install#

#Fastcam outline how to#

04 If MTC cutting nesting software expired and can`t upgrade, how to solve? # As well, if you want to cut several time the same shape from the same metal sheet, the cutting software has the nesting facility. Or if you are using AutoCAD, you made the drawing with the CAD software you process it with FastCAM to have a cutting program. You made the drawing of the part to be cut with the FastCAM cutting nesting software, After you setting the Fast Path, this drawing is automatically translated in a cutting program. 03 How does the programming work on CNC cutting machine? # When you use the SteelTailor machine, Please choose “START”. The list is :-Burny 3 5 10,Edge EIA,ESSI,Fagor,Lynx EIA,START,KangPu,Koike,FastCNC 02 For the FastCAM software On installation it asks us to choose the control type? # Another way is, use Fast CAM directly to make the drawings, then translate in a cutting program with the G and M codes and to save it in the memory stick, then plug in the USB port of SteelTailor. This one is saving on a memory stick and loaded into SteelTailor via the USB port.

#Fastcam outline Pc#

dxf, as AUTOCAD by example) then using Fast CAM loaded on the same PC translate in a CNC cutting program. 01 How are the FAST CAM programs uploaded to the CNC cutting machine? #Ĭoncerning Fast CAM, the CNC cutting drawings are made on a PC, using a CAD program (which can saved as.

0 kommentar(er)

0 kommentar(er)